Choose your own laser equipment

Published:2020-02-24 Browse:140Editor in charge:DNE LASER

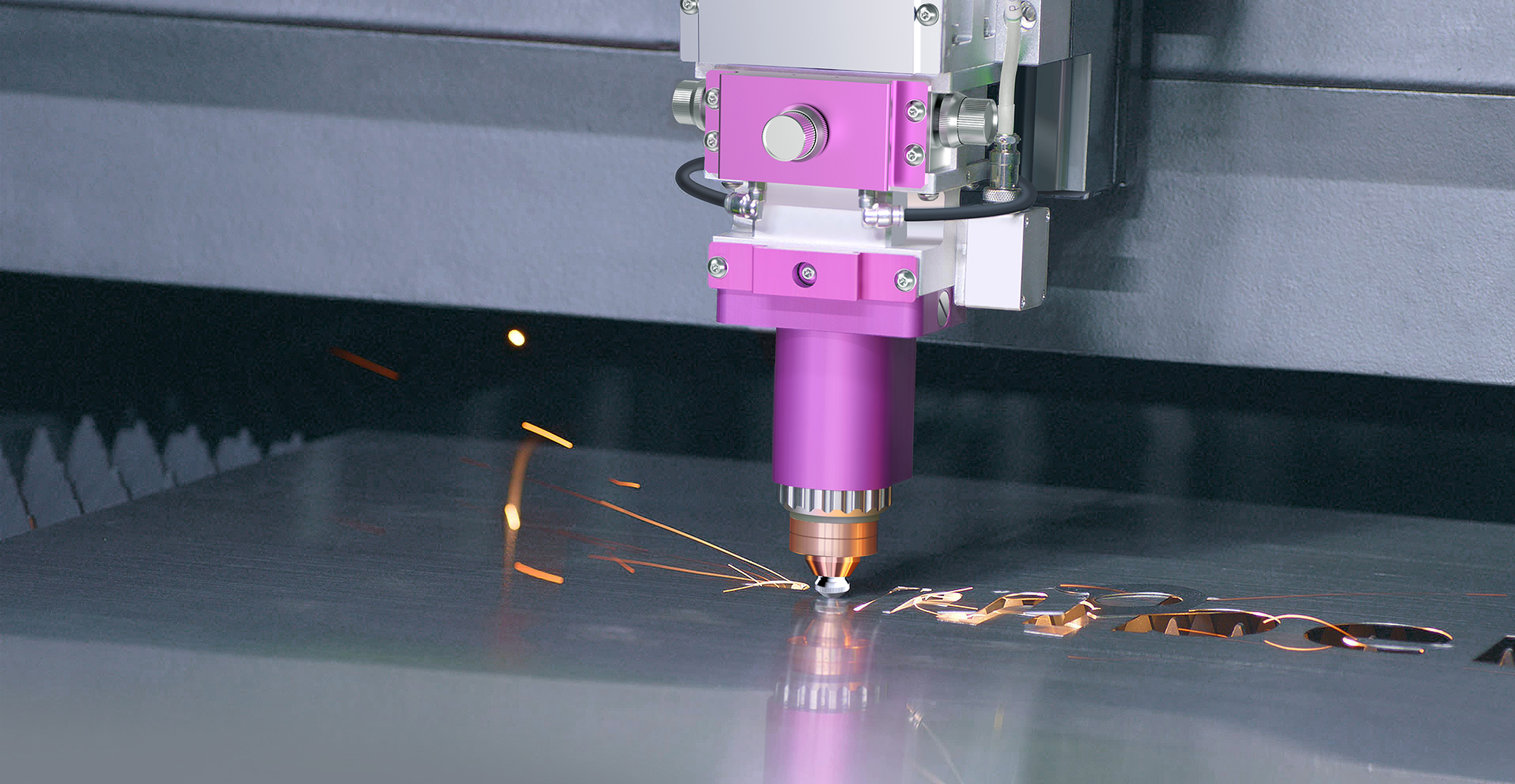

Laser cutting is to replace the traditional mechanical knife with an invisible light beam. It has the characteristics of high precision, fast cutting, not limited to cutting patterns, automatic layout, saving materials, smooth cutting edge, and low processing costs. It will be improved or replaced traditional metal cutting process equipment gradually.

1. The mechanical part of the laser cutter head is not in touch with the workpiece, and will not cause scratches on the surface of the workpiece during cutting; the cutting speed is fast, the cutting edge is smooth and flat, and generally no subsequent processing is required; the cutting heat-affected zone is small, the plate deformation is small, and the cutting gap seam is narrow (0.1mm ~ 0.3mm).

There is no mechanical stress and no shear burrs on the edge; the processing accuracy is high, the repeatability is good, and the surface of the material is not damaged; the CNC programming can process any plan, and can cut the whole board with a large breadth, without opening the mold, which is economical and time-saving.

2. The current application directions of laser cutting equipment on the market are mainly in the following three categories:

The first category is the processing materials used for decoration, advertising, lamps, kitchenware, thin sheet metal parts, electrical cabinets, elevator panels, engineering boards, and high and low switch cabinets. These materials are generally thin, like stainless steel plates with a thickness of 1-5mm. This material can be cut with a medium-power laser cutting machine. For cutting such materials, users can also consider buying a YAG laser cutting machine or a 500W fiber laser cutting machine.

The second category is cutting plastic (polymer), rubber, wood, paper products, leather, and natural or synthetic organic materials. Since these items are not metal products, the absorption of laser is also different, so CO2 laser cutting machine is the best choice for cutting these materials.

The third type is 8-20mm low-carbon steel and 12mm stainless steel. This type of material requires a high-power laser cutting machine to cut quickly and instantly. We can consider buying a high-power fiber laser cutting machine or a high-power CO2 laser Cutting Machine.

Therefore, when we choose laser equipment, we must not only consider the characteristics of our product materials, but also consider the performance of the laser equipment, so that we can find the laser equipment which is suitable for our industry products.

Bystronic (Shenzhen) Laser Technology Co., Ltd.

Bystronic (Shenzhen) Laser Technology Co., Ltd.