How to judge the cutting quality of laser cutting machine?

Published:2021-07-06 Browse:299Editor in charge:DNE LASER

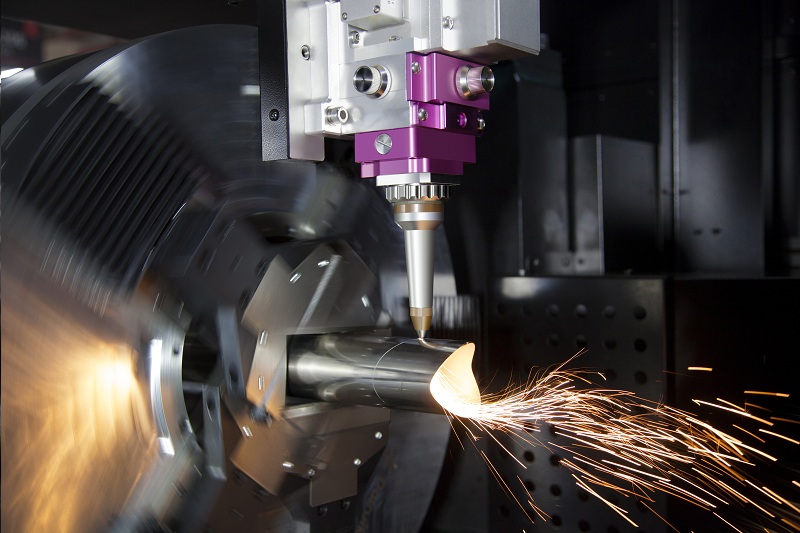

Today, with the continuous development of science and technology, the use of lasers is becoming more and more extensive, and it also brings more convenience to our lives. As a type of cutting machine commonly used in the industry, laser cutting machines are often used in the industry. Then, in the face of many laser cutting machines, how do we judge the cutting quality of laser cutting machines when we are purchasing?

1. Judging the perpendicularity of the cutting quality of the laser cutting machine

When we cut the plate, we usually do it through computer graphics, and then laser cutting machine to cut. Then this kind of laser cutting machine in the cutting process, especially at the edge, is it vertical, and its cutting surface is oblique. Whether the degree is too large, if the verticality is higher, the cutting accuracy of the laser cutting machine is higher.

2. Judge the roughness of the cutting quality of the laser cutting machine

When the laser cutting machine finishes cutting the product, its section will form some relatively vertical lines, and the depth of this line determines the roughness of the cutting surface. The shallower the section line, the smoother the cut surface. On the contrary, the more the section The deeper the texture, the rougher the cut surface.

Three, judge the lines of the cutting quality of the laser cutting machine

When we usually use a laser cutting machine, especially when processing some thick plates, the molten metal will not appear in the cut below the vertical laser beam, but will spray out at the rear of the laser beam. As a result, curved lines are formed on the cutting edge, and the lines closely follow the moving laser beam. In order to correct this problem, reducing the feed rate at the end of the cutting process can greatly reduce the formation of the lines.

The points introduced above are some tips to determine the cutting quality of the laser cutting machine. When we select the laser cutting machine, we need to operate on-site to see the cutting effect. In addition, according to different sheet thicknesses, there are some matching skills. The type of laser cutting machine, this can be selected according to the requirements of the plate that we cut on weekdays!

Bystronic (Shenzhen) Laser Technology Co., Ltd.

Bystronic (Shenzhen) Laser Technology Co., Ltd.