What are the advantages of fiber laser cutting machine in cutting applications

Published:2020-02-24 Browse:90Editor in charge:DNE LASER

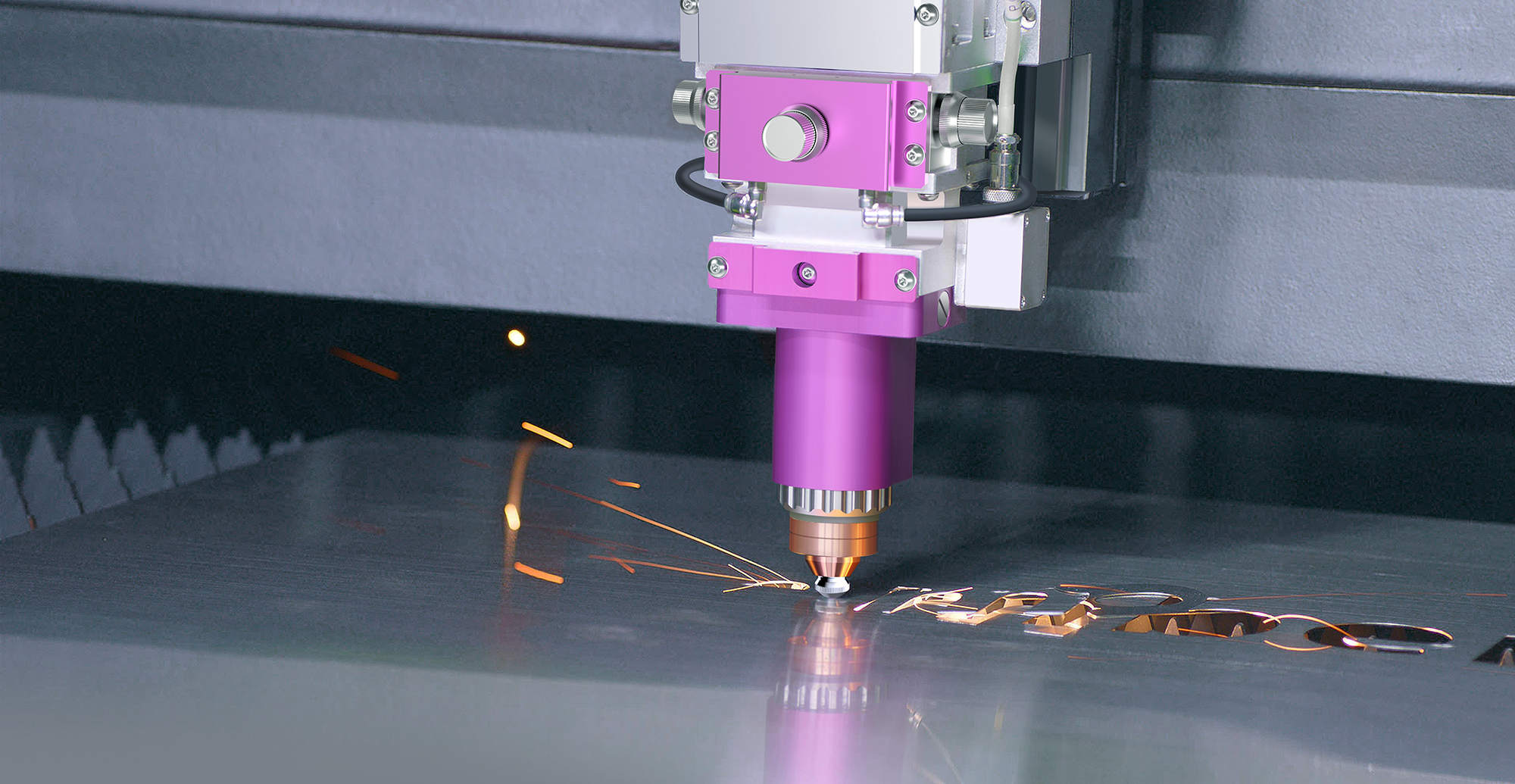

As one of the core devices of high-end manufacturing equipment, fiber laser cutting machine meets the background of industrial manufacturing transformation, and is qualified for the requirements of multidimensional machining applications with high difficulty and great changes. The advantages of cutting processing of fiber laser cutting machines make it very popular in the market, and address the pain points of high production cost and low production efficiency effectively, so there is a huge market space. Taking the application of laser cutting as an example, comparing the processing characteristics of fiber laser cutting machine, CO2 laser cutting machine, and YAG solid laser cutting machine, we can peek into the advantages and development potential of fiber laser in laser cutting application.

Low-cost and high-efficiency, the highlights of fiber laser cutting machine

(1) Operation requirements and maintenance

CO2 laser needs to adjust the optical path, and the effect of optical path adjustment will affect the cutting quality, so the operator needs to have certain skills and need to maintain the external optical path; YAG solid laser thermal lens effect is obvious and needs frequent maintenance.

CO2 laser needs to adjust the optical path, and the effect of optical path adjustment will affect the cutting quality, so the operator needs to have certain skills and need to maintain the external optical path; YAG solid laser thermal lens effect is obvious and needs frequent maintenance. The fiber laser’s fiber transmission is free of adjustment, maintenance, with high stability and easier to operate.

(2) Cutting speed and effect

The cutting speed of the fiber laser is 2-3 times the CO2 laser of the same power, especially in the cutting of thin metal plates, the cutting speed of the fiber laser cutting machine has obvious advantages in this three types of laser cutting machines. Fiber laser cutting machine has better beam quality, narrower cutting gap and smoother cutting edge.

(3) Material applicability and application industries

Fiber laser is more in line with the processing requirements of sheet metal manufacturing, 3C home appliance industry and new energy industry.

(4) Energy consumption and comprehensive cost

The photoelectric conversion rate of the fiber laser is more than 30%, the photoelectric conversion rate of the same power CO2 laser cutting machine is about 10-15%, and the photoelectric conversion rate of the solid laser is 3%. Fiber laser power consumption is only 20-30% of CO2 laser of the same power, so its comprehensive cost is lower.

The fiber laser cutting is more precise, the focusing focus can reach 25um, the heat-affected zone is small, the cutting gap is narrow, and the workpiece deformation is small. As a flexible processing method, DNE laser cutting machine can be combined with an automatic control system to achieve automatic tracking, automatic edge detection, and automatic feeding, which improves the production efficiency greatly. It is widely used in metal cutting and has better performance, which can meet the requirements of fine cutting processing better.

Bystronic (Shenzhen) Laser Technology Co., Ltd.

Bystronic (Shenzhen) Laser Technology Co., Ltd.