Laser cutting of stainless steel guardrail tube

Published:2020-02-21 Browse:125Editor in charge:DNE LASER

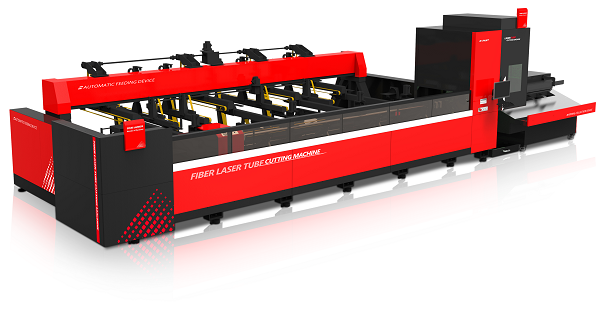

There are many types of guardrails, and the materials are mainly stainless steel and other metal composite tube. Stainless steel has the characteristics of corrosion resistance, anti-rust, beautiful appearance and sturdy, which are widely used indoors and outdoors. The most used outdoor areas are roads, streets, municipalities, landscapes, green belts and other areas, while indoors are mostly used for family balconies, stairs, schools, hotels, entertainment venues, etc. The guardrail is composed of many square tubes or round tubes. The laser cutting machine for pipes can efficiently cut and punch metal pipes such as stainless steel.

On the one hand, it improves the processing efficiency and productivity, on the other hand, it also lays the foundation for the production of high-quality guardrails. The pipe cutting machine is used for processing, which greatly improves the processing quality. In addition to the above two main advantages, the tube laser cutting machine has the following characteristics:

Convenience: It is not constrained by the shape, and the shape required to be cut can be input by software programming to achieve precise cutting. The operation is convenient and intelligent.

Flexible: Provide customers with individual processing requirements quickly, and the shape can be carefully changed at any time through the software, and the change will not affect the production process of the product.

Accuracy: The tube laser cutting machine uses non-contact processing, and there is generally no material deformation during the cutting process. Bystronic new generation professional pipe cutting machine can cut metal pipes without being constrained by shape, and achieve high quality and high efficiency cutting.

Bystronic (Shenzhen) Laser Technology Co., Ltd.

Bystronic (Shenzhen) Laser Technology Co., Ltd.