Three minutes to take you to understand the application range of laser cutting machine

Published:2021-04-16 Browse:195Editor in charge:DNE LASER

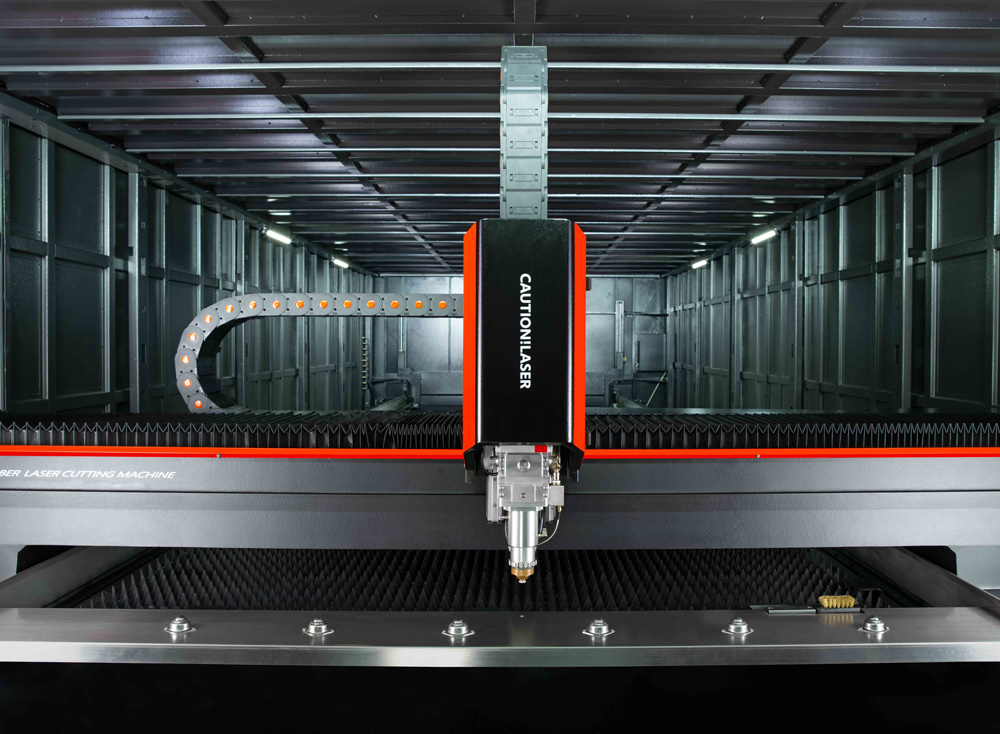

Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to the cutting pattern, automatic typesetting, saving material, smooth cutting, and low processing cost. It will gradually improve or replace it. Traditional metal cutting process equipment. The mechanical part of the laser cutter head of the laser cutting machine has no contact with the workpiece, and will not cause scratches on the surface of the workpiece during work; the laser cutting speed is fast, the incision is smooth and flat, and generally does not require subsequent processing; the cutting heat affected zone is small, and the plate deformation is small. The slit is narrow. With the continuous development of laser technology, laser cutting machines have gradually replaced traditional cutting methods with their flexibility and flexibility.

Laser cutting machine is a processing machine that everyone is familiar with now. According to the classification of cutting materials, it can be divided into metal cutting machine and non-metal cutting machine. So which industries can it be used in?

Mainly based on the following major industries:

Kitchenware industry: The traditional processing methods of the kitchenware manufacturing industry face problems such as low work efficiency, high mold consumption, and high cost of use. The laser cutting machine has fast cutting speed and high precision, improves processing efficiency, and can realize customized and personalized product development, solves the troubles of kitchenware manufacturers, and is recognized by kitchenware manufacturers.

Automobile manufacturing industry: There are also many parts and materials in automobiles, such as automobile brake pads. In order to improve the stability of the automobile, it is necessary to ensure the cutting accuracy. The traditional manual labor is difficult to achieve the accuracy, and the efficiency is low. The laser cutting machine can be used for processing. Faster batch processing, high precision, high efficiency, no burrs, and one-time molding advantages. These are the reasons why laser cutting machines are widely used in the automotive industry.

Advertising metal word industry: The traditional processing equipment for advertising generally uses materials such as processing advertising fonts. Due to the processing accuracy and the unsatisfactory cutting surface, the probability of rework is quite high. The high-precision laser cutting technology does not require secondary rework, which greatly improves work efficiency and saves enterprise costs.

Sheet metal processing industry: With the rapid development of sheet metal processing technology, traditional sheet metal cutting equipment can no longer meet the current process and cutting shape requirements. Laser cutting has gradually replaced traditional equipment with its high level of flexibility and fast cutting speed. , The wide application of fiber laser cutting machine in sheet metal processing is an inevitable trend.

Bystronic (Shenzhen) Laser Technology Co., Ltd.

Bystronic (Shenzhen) Laser Technology Co., Ltd.